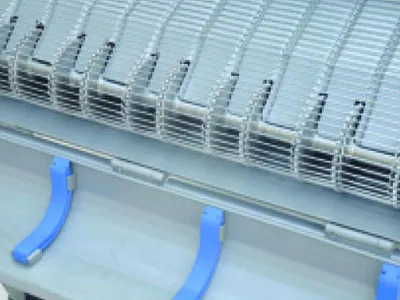

MultiDrum Breader

The breading machine features 3 drums. The bone-in or boneless products are transported into the three drums through the flatbed. After being turned over and mixed in the drum, the flour coated products are transported by the conveyor belt for discharging. The multidrum machine is designed for the pre-dusting and final coating process of products like chicken popcorn. The bone-in or boneless products processed feature coarse crunchy golden surface.

Features

- Production capacity: over 2000 kg/hour (take chicken popcorn as example).

- Coating speed is variable-frequency adjustable, and coating angle and thickness is controlled.

- Adopting vibrating discharging system ensures even product output and removes the excessive flour coatin. The output belt automatically transports products to the standard height (1000mm±100mm).

- All the electrical parts are water proof.

- featuring split structure for easy clean.

- Little flour dust scattering ensures clean working environment in the factory.

- Elevator conveyor belt is applied to transport the flour to the flatbed (optional) to improve efficiency.

- All parts contacting food are made of food-grade stainless steel, meeting HACCP standard.

- Button control system and simple English operation interface.

Technical parameter

| Model |

|

|

| Speed of the belt | 4~20m/min adjustable | |

| Input height | 1050±50mm | |

| Output height | 950±50mm | |

| Power | 2.7kW | 3.31kW |

| Drum No. | 2 | 3 |

| Width of the belt | 600mm | 1000mm |

| Overall dimensions | 4350×1510×1860mm | 4350×2010×1860mm |