Preduster Pro

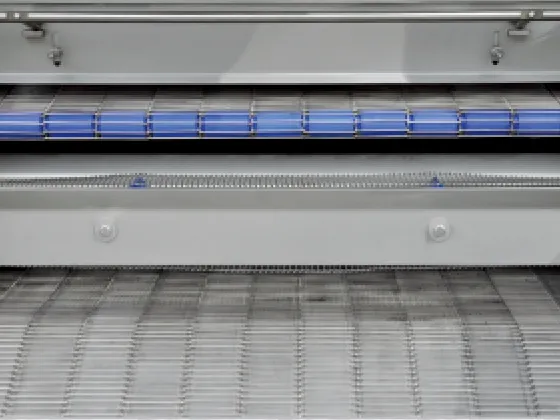

GFJ600-VII drum breader coats the products with a even layer of flour. The bone-in or boneless product enters the drum through the flour flatbed, which avoids batter loss, and increases the quantity of the flour on the products surface. After vibrating screen, the gathered dough will be removed, and the recycled flour is conveyed back to machine feeding parts by the bottom conveyor. The food processed features a coarse crunchy golden surface. The breading machine is not only used for flouring and breading processes in mass production, also suitable for the production of chicken nuggets, chicken popcorn, fish nuggets, etc.

- This preduster is equipped with multiple sensors that can precisely control the amount of powder coating, fitting for high-speed production;

- Visual control of parameters, consistent quality, standardized production, suitable for large-scale automatic production line;

- Motors made of stainless steel whose surface is smooth and sealed so that protection cover is not needed; small noise and easy to clean, reducing pollution and meeting the hygienic standard;

- Casters can be immediately adjusted so that forklift is unnecessary and the time for production preparation is reduced;

- Fine wire mesh belt can reduce mesh print on products;

- Improved configuration of the whole preduster, including automatic supplementation of powder, online monitoring, and precise control of powder-coating technology;

- Powder-coating at the upper part of the input belt is controllable, making the powder more adhesive;

- Imported stainless steel motor with high safety degree and performance.

| Model |

|

|

| Conveying speed | 5-25m/min frequency control | |

| Input height | 1000mm | |

| Output height | 1050±50mm | |

| Power | 3.93kW | 5.9kW |

| Belt width | 600mm | 1000mm |

| Overall dimensions (mm) | 2730×1610×2150mm | 2730×2010×2150mm |